Communications Industry

Sigma Technik Limited can provide rapid prototyping and customized production services, and provide high-quality communication equipment to customers at competitive prices.

Why Choose Us for communications Manufacturing?

Sigma Technik Limited's advantages and capabilities in the manufacturing of communication components. Adopting the latest technology and advanced manufacturing processes to achieve efficient and cost-effective manufacturing of communication components. At the same time, we have extensive technical knowledge, experience, and cutting-edge technology, which puts us at the forefront of electronic equipment manufacturing.

Advanced technology and processes

Sigma Technik Limited adopts the latest technology and advanced manufacturing processes to produce high-quality and high-performance communication equipment and components.

quality control

Sigma Technik Limited has an experienced manufacturing team with extensive technical knowledge and management capabilities, capable of providing professional services and support.

Customization

Sigma Technik Limited can provide rapid prototyping and customized production services, allowing for customized production based on customer needs, while also providing high-quality prototypes in a short period of time.

lower production cost

Sigma Technik Limited can provide customers with high-quality communication equipment and components at competitive prices, helping them reduce production costs and improve market

Prototyping solutions for the communication industry

In the communication industry, prototyping solutions need to consider factors such as product safety, reliability, and stability. Communication equipment and systems need to undergo detailed testing and evaluation to ensure compliance with industry standards and regulations. Therefore, during the prototype production and testing process, it is necessary to pay attention to these factors and adjust and improve the prototype as needed.

Rapid prototyping

Create your prototype using the selected manufacturing method. When making prototypes, attention should be paid to the selection of materials and the details of the manufacturing process to ensure that a prototype that meets the requirements is produced.

Design and establish digital models.

Use computer-aided design (CAD) software or similar software to design your digital model. When designing a digital model, it is necessary to consider the appearance and functionality of the product.

Choose the appropriate material

Choose materials that meet product requirements, such as plastic, metal, or composite materials. Choosing suitable materials also requires consideration of factors such as production costs and material availability.

Choose the appropriate manufacturing method

Select appropriate manufacturing methods based on your digital model and materials, such as 3D printing, injection molding, and CNC machining. Different manufacturing methods have their own advantages and disadvantages, and you need to choose the most suitable method based on your specific needs

Testing and Evaluation

Test your prototype to evaluate its appearance and functionality. If the prototype needs to be improved, it needs to be designed, manufactured, and tested again.

Prototyping solutions for the communication industry

The production materials of communication equipment need to consider various factors to ensure the electrical, mechanical, thermal, and corrosion resistance of the equipment, in order to meet the design requirements of the equipment.

Metal

Such as aluminum alloy, steel, copper, etc., commonly used for making components such as frames, antennas, cables, etc.

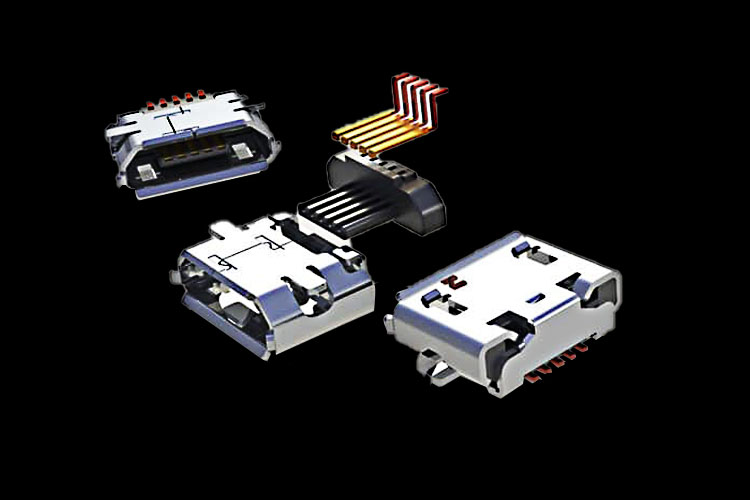

Plastics

Such as ABS, PC, PA, POM, etc., commonly used for making components such as shells, plugs, and connectors.

glass fibre

Such as glass fiber reinforced plastic (FRP), carbon fiber reinforced plastic (CFRP), etc., commonly used in the production of components such as antennas, masts, brackets, etc.

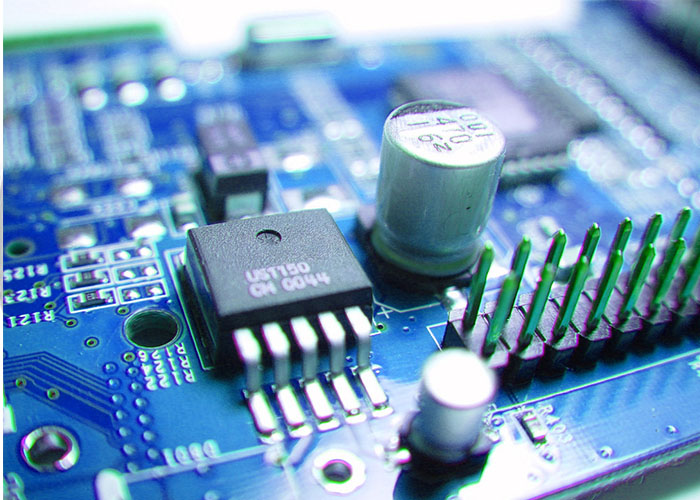

circuit board

Such as glass fiber copper clad plate (FR-4), aluminum substrate, ceramic substrate, etc., commonly used in the production of circuit boards.

Customized parts for the Communications industry

The manufacturing of communication components requires familiarity with different manufacturing processes and technologies, such as injection molding, die-casting, precision machining, etc., as well as familiarity with corresponding equipment and tools. Communication component manufacturers need to have relevant manufacturing capabilities and experience, and be able to customize production according to customer needs.

Customized parts for the automotive industry

Customized parts in the communication industry can help communication equipment and systems meet different needs and application scenarios, improve their performance and reliability, and reduce production and operational costs.

Let’s start a great partnership journey!

Frequently Asked Question

The design of communication products should combine usage scenarios and needs, reasonably design product dimensions and materials, etc. to ensure product performance and reliability.

High quality materials should be used in the production of communication products, such as materials with good properties such as fire resistance, oxidation resistance, and UV resistance.

In the manufacturing process of communication products, it is necessary to optimize the manufacturing process, strengthen quality control, and ensure the stability and reliability of the product.

Before installing communication products, training should be conducted to ensure proper installation and avoid unnecessary problems and losses.

How to Work With Us

24/7 Support, Sigma provides the most effective solutions for low volume production and rapid prototyping, just a few steps to experience our excellent customer services.

Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota