rapid injection molding

Rapid injection molding services provide fast quotation, design feedback, multiple material selection, high-precision, and customizable services.

On-demand Rapid Injection Molding

Sigma’s rapid tooling service helps you to have the low volume to large volume plastic parts done, with no compromise on the material selection.

- No MOQ required

- Get the rapid tooling as fast as 2 weeks

- Free DFM

- 24/7 engineering support

Our rapid injection molding Application

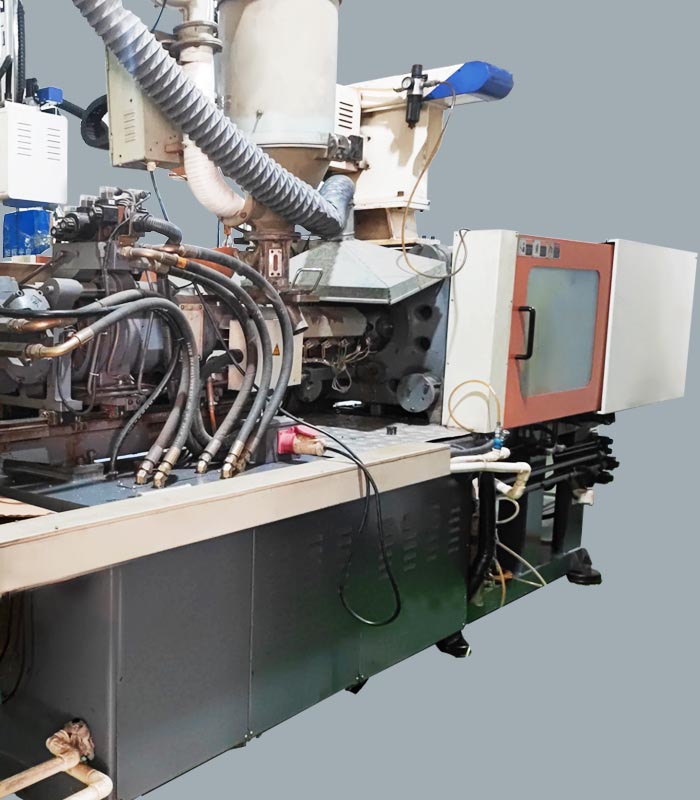

Sigma Technik Limited's rapid injection molding service injects molten plastic materials into molds using injection molding machines and molds, and cools and solidifies them over a certain period of time, ultimately forming the required plastic parts. This manufacturing process is usually suitable for producing small and medium-sized plastic parts, which can obtain high-quality and precise parts in a short period of time.

Plastic Injection Molding

Injection molding is a common manufacturing process to produce low volume to large volumes of parts typically made out of plastic. The process involves injecting molten material into a mold and letting it cool to a solid-state.

Liquid Silicone Rubber Molding

Liquid Silicone Rubber is known as LSR, which is a process used to produce parts made from silicone rubber, widely used create products such as medical devices, automotive parts, baby care products, and many others.

2K Injection molding

2K injection molding is a manufacturing process in which two different types of plastic materials are molded together in a single operation to create a single homogeneous component. This process allows for efficient and cost-effective production of high-quality parts that can perform unique functions.

Overmolding and Insert Molding

Overmolding / Insert molding combines two or more materials into a single part, one of the material is usually soft and flexible, or metal. The purpose of overmolding/insert molding is to add functionality, improve grip, provide protection, or enhance aesthetics.

From Rapid Prototyping to Production

It’s not easy for the startups to talk to the mold makers, our easy access to rapid tooling helps many startups successfully make it happen, with our short run flexibility and low setup fees.

We are committed to helping startups with design for manufacturing, hence they can startups can avoid costly mistakes and delays later on.

From Rapid Prototyping to Production

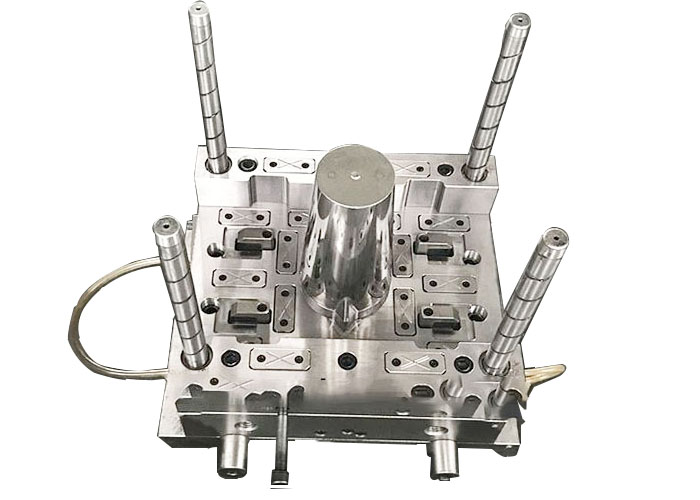

Rapid Tooling

Ideal for low volume production, and bridge production quantities, mainly used for design validation, market research.

- No MOQ required

- Tooling life up to 10K shots

- Lead time as fast as 2 weeks

- Steel tooling

Production Tooling

Ideal for large volume production, batch starting from 10,000 units. Relatively higher Tooling costs, but extreme low part price.

- No MOQ required

- Up to 1M molding shots

- Steel tooling & multi-cavity tooling

- Automatic tooling

Rapid injection molding materials

ABS

ABS is a type of plastic with high strength, hardness, and toughness. It has good impact resistance and wear resistance, and is suitable for manufacturing shells, components, and models.

PC

PC is a transparent, high-strength, high-temperature resistant, and excellent electrical insulation material. It is suitable for manufacturing transparent components, electronic components, and automotive components.

PP

PP is a relatively flexible material with excellent corrosion resistance and high temperature resistance. It is suitable for manufacturing containers, pipelines, baby bottles, etc.

PA

PA is a material with high strength, high rigidity, and wear resistance. It is suitable for manufacturing gears, bearings, brackets, etc.

POM

POM is a material with excellent wear resistance, toughness, and rigidity. It is suitable for manufacturing gears, bearings, pulleys, etc.

Advantages of Rapid Injection Molding

Rapid Injection Molding is the ideal process to produce low volume plastic parts with high quality. Sigma’s exceptional experience in this field also helps you get the parts economical.

- Low investment in tooling

- Excellent part cosmetics and surface finish

- Stable and Repeatable

- Break the design limit

- Low scrap rate

- Large material selection

- cost at higher volumes

Fast delivery

Sigma Technik Limited adopts rapid injection molding technology, which can complete large-scale production in a short period of time while providing fast delivery services, allowing customers to quickly bring their products to the market.

Diversed material choices

Sigma Technik Limited can provide a variety of injection molding material options, including common materials such as ABS, PC, PP, PA, POM, etc. At the same time, it can provide injection molding services for special materials according to customer needs.

Customized Services

Sigma Technik Limited can provide custom injection molding services, ccording to customer requirements, including product design, material selection, surface treatment, and other aspects to meet the different needs of customers.

Competitive Price

The injection molding service prices are competitive, providing customers with high-quality injection molding products and services while ensuring reasonable prices.

Rapid Injection Molding Service Application

Let’s start a great partnership journey!

Rapid Injection Molding FAQs

Burrs appear on the surface of the product, which affects its aesthetics and safety. The solution can be to adjust the parameters of the injection molding machine, such as temperature, pressure, speed, etc., or to perform post-processing, such as polishing, sandblasting, etc.

The warping deformation of the product is usually caused by unstable parameters such as temperature and pressure of the injection molding machine, or improper mold design. The solution can be to adjust parameters such as temperature and pressure, or to redesign the mold.

The occurrence of bubbles inside the product may be due to the high temperature of the injection molding machine and the high moisture content of the material. The solution can be to reduce the temperature of the injection molding machine, adjust the water content of the material, increase the pressure of the injection molding machine, etc.

The product size deviation is too large, which may be caused by material thermal expansion, mold deformation and other reasons. The solution can be to adjust parameters and optimize mold design based on material characteristics.

How to Work With Us

24/7 Support, Sigma provides the most effective solutions for low volume production and rapid prototyping, just a few steps to experience our excellent customer services.

Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota