Robotics Industry

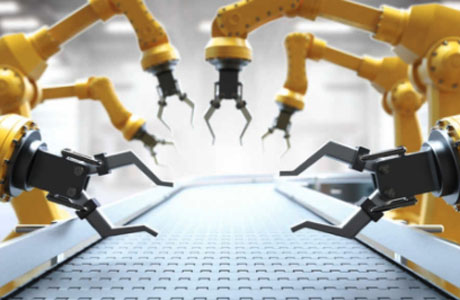

Rapid prototyping and on-demand production technology can help the robotics industry achieve customized production and meet the personalized needs of customers. Therefore, rapid prototyping and on-demand production technology have important application value in the robotics industry.

Why Choose Us For The Robotics Industry?

Choosing Sigma Technik Limited to produce robot prototypes and parts can provide advantages such as diverse manufacturing technologies, excellent manufacturing quality, fast delivery, personalized customization, and professional team support. This can help customers quickly respond to market demand, improve product quality and competitiveness.

Rapid delivery

Sigma Technik Limited can quickly manufacture robot prototypes and parts, and provide fast delivery services, which can complete manufacturing and deliver to customers in a short period of time. This can greatly shorten the product development and production cycles, helping customers quickly respond to market demand.

Multiple manufacturing technologies

Sigma Technik Limited can provide a variety of manufacturing technologies, including 3D printing, CNC machining, injection molding, etc., and can choose the most suitable manufacturing technology according to different needs. These technologies can manufacture parts and prototypes of various materials, including metals, plastics, resins, ceramics, etc.

Personalized customization

Sigma Technik Limited can provide personalized customization services to customers, manufacturing robot prototypes and parts that meet their customized needs and requirements. This can help customers achieve personalized production and customized services, and improve market competitiveness.

Professional team support

Sigma Technik Limited has a professional team consisting of engineers, designers, manufacturers, and sales personnel, providing comprehensive technical support and services. Customers can receive the highest quality service and support through RapidDirect's professional team.

Rapid Prototyping Solutions For The Robotics Industry

Rapid prototyping solutions in the robot industry include rapid prototyping, 3D printing, CNC processing, injection molding and low-cost manufacturing, which can help enterprises quickly respond to market demands, improve production efficiency and reduce production costs.

Rapid prototyping

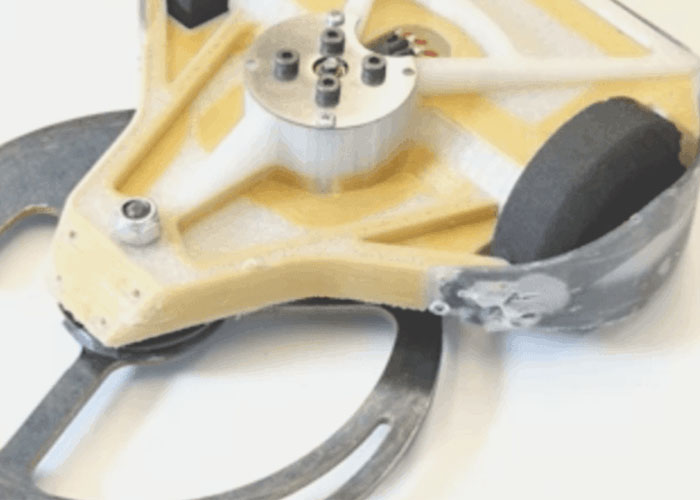

In the robotics industry, rapid prototyping technology can help companies quickly manufacture models and samples of robot components and shells to validate design solutions and improve production efficiency. At the same time, rapid prototyping technology can also be used to manufacture models and samples of robot shells for aesthetic and functional testing.

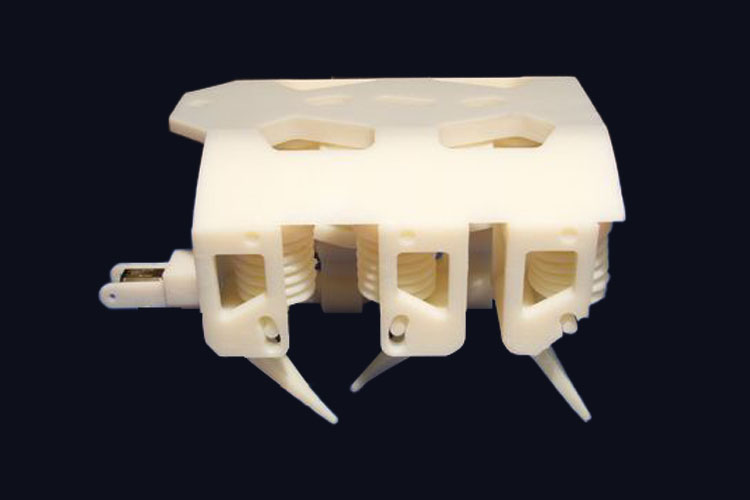

3D Printing

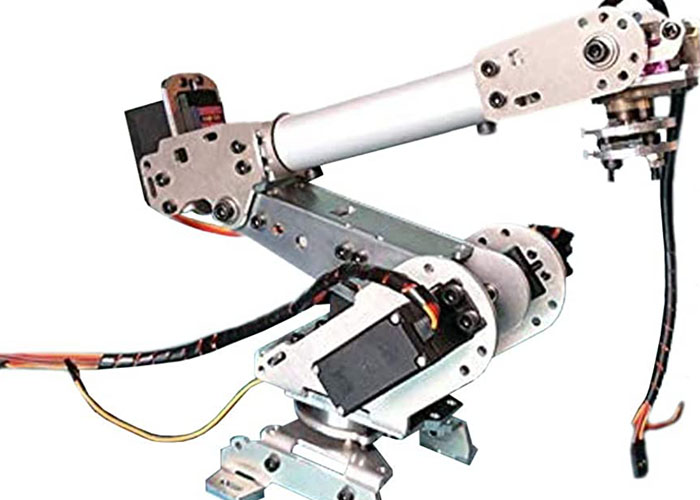

3D printing technology can quickly manufacture robot components and accessories, while also enabling personalized customization according to customer needs. In the robotics industry, 3D printing technology has been widely used in the manufacturing of various robot components, such as robotic arms, servo motors, gears, etc., which can greatly improve production efficiency and reduce production costs.

CNC Machining

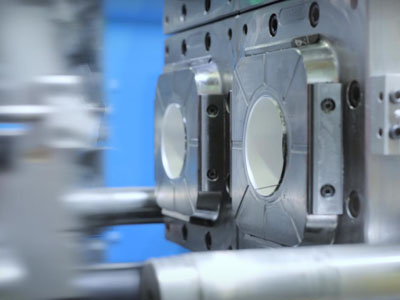

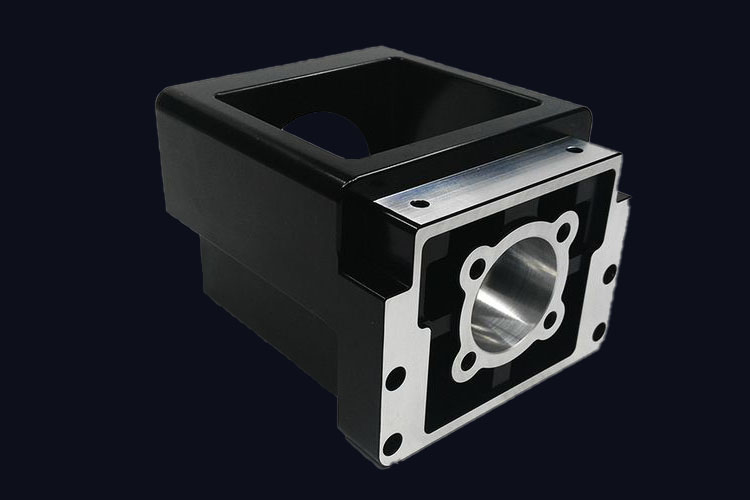

CNC machining technology can manufacture high-precision and high-quality robot components and accessories, including materials such as metal, plastic, resin, etc. In the robotics industry, CNC machining technology is widely used to manufacture various robot components and accessories, such as robotic arms, gears, bearings, etc.

Injection molding

Injection molding technology can produce high-precision and high-quality robot shells and components, including materials such as plastic and resin. In the robotics industry, injection molding technology is widely used to manufacture robot shells, accessories, and components.

Robotics Industry Manufacturing Materials

There are various types of materials for prototype production in the robot industry, and the specific selection of which material depends on the functional and performance requirements of the required components, as well as production costs and other factors.

ABS

ABS is a commonly used plastic material with high strength, good rigidity, and strong impact resistance, making it suitable for making components such as robot shells and robotic arms.

PA(nylon)

PA is a high-strength and high toughness plastic material with characteristics such as wear resistance, corrosion resistance, and high temperature resistance, suitable for making robot gears, bearings, and other components.

Aluminium

Aluminum alloy has the characteristics of lightweight, high strength, and corrosion resistance, making it suitable for making components such as robot arms and connectors.

stainless steel

Stainless steel has characteristics such as corrosion resistance and high strength, making it suitable for making robot components such as robotic arms and connectors.

carbon fibre

Carbon fiber has the characteristics of lightweight, high strength, and good rigidity, making it suitable for making components such as robot shells and robotic arms.

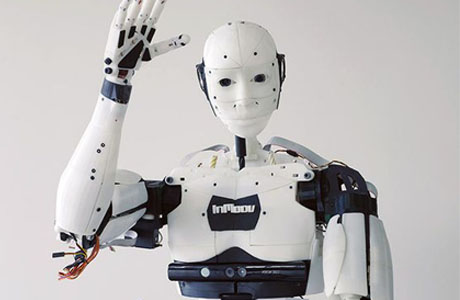

Robotics Industry Application

The rapid prototyping technology of robots is widely used in the robotics industry, which can help enterprises quickly validate design solutions, improve production efficiency, and reduce production costs.

Customized parts for the Robotics Industry

Customizing parts for the robotics industry requires multiple steps such as requirement determination, design drawings, manufacturing method selection, manufacturing, inspection, and testing, and requires professional designers and manufacturing technical support.

Let’s start a great partnership journey!

Frequently Asked Question

The first step in rapid prototyping of robots is design. If the design is unreasonable or has problems, it may lead to subsequent manufacturing and usage problems, such as loose connections of robot components and inflexible movement of robotic arms.

The materials used for rapid prototyping of robots are usually plastic, metal, etc. If the materials are not selected properly or of poor quality, it may lead to problems such as insufficient strength and easy damage of components, affecting the lifespan and stability of the robot.

In the process of rapid prototyping for robots, various manufacturing equipment and tools need to be used. Improper operation or insufficient manufacturing accuracy may lead to inaccurate component dimensions, poor surface quality, and other issues, affecting the performance and stability of the robot.

Although rapid prototyping of robots can quickly verify design solutions and manufacture components, the cost is relatively high. Improper cost control may lead to high production costs and affect the market competitiveness of products.

How to Work With Us

24/7 Support, Sigma provides the most effective solutions for low volume production and rapid prototyping, just a few steps to experience our excellent customer services.

Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota