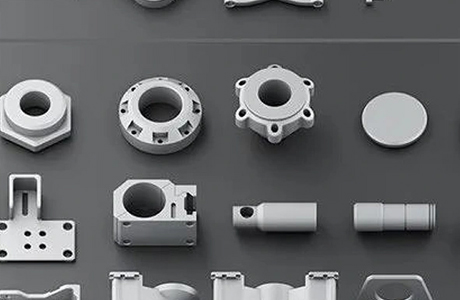

Part quality assurance

We ensure the quality of producing high-quality parts by applying strategies such as quality management system, supply chain control, standard specifications, employee training, advanced equipment, quality control, and continuous improvement.

How to improve the quality of parts processing

Strict quality control process

We establish a clear part processing process to ensure that each production step follows the prescribed quality control measures. This includes detailed specifications and procedures for material preparation, processing technology, measurement and inspection, packaging, and other aspects.

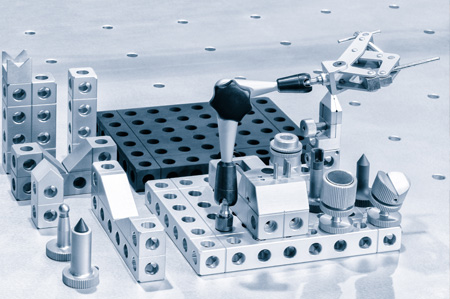

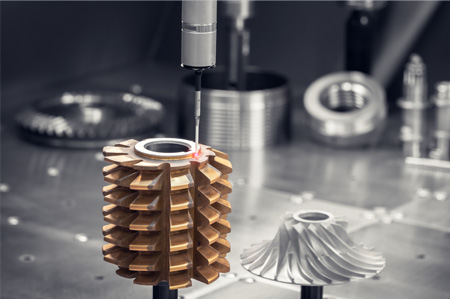

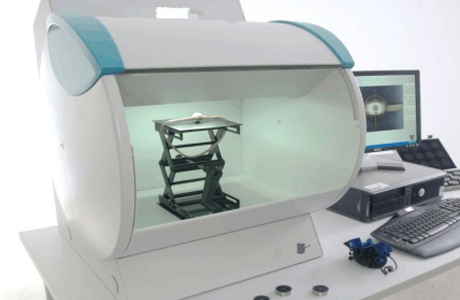

Professional processing equipment and tools

We ensure the use of professional processing equipment and tools to meet the requirements of parts processing. Select appropriate machine tools, cutting tools, fixtures, and measuring equipment to ensure the accuracy and stability of the machining process.

Qualified Supply Chain Management

We ensure that the supply chain from raw material suppliers to processing plants meets quality standards and requirements. Establish stable cooperative relationships with reliable suppliers, evaluate and audit suppliers, and ensure that the provided raw materials meet the specified quality requirements.

Strict inspection and testing

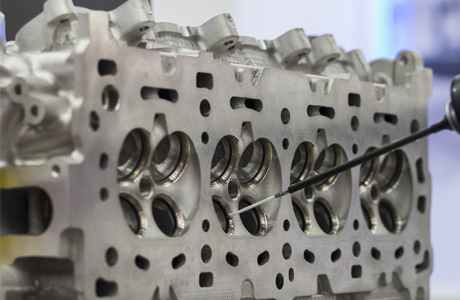

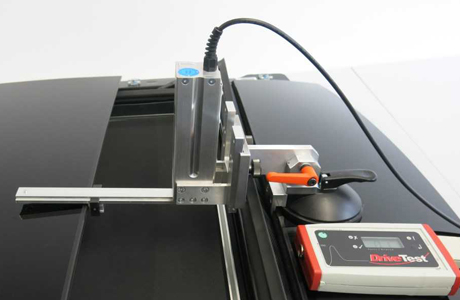

We conduct necessary inspections and tests during the processing process to ensure the quality of the parts processed. Including dimensional measurement, geometric measurement, surface quality inspection, etc., using appropriate inspection equipment and testing methods to ensure that the parts meet the specified quality standards.

Quality assurance measures plan

Establish standards and norms

We establish clear parts processing standards and specifications, including design requirements, processing techniques, dimensional requirements, surface quality requirements, etc. Ensure that all relevant personnel are aware of these standards and specifications and strictly adhere to their requirements.

Strictly control process parameters

We determine appropriate process parameters for each machining process, including cutting speed, feed rate, cutting depth, etc. Ensure accurate control of these parameters to ensure the consistency and stability of part processing.

Adopting advanced processing equipment and tools

We choose high-precision and highly stable processing equipment and tools to ensure the accuracy and reliability of the processing process. Regularly maintain and maintain equipment to maintain its good working condition.

Strictly control the quality of raw materials

We cooperate with reliable raw material suppliers to ensure that the raw materials used meet the specified quality standards and requirements. Conduct incoming inspection of raw materials, including chemical composition analysis, physical performance testing, etc.

Implement strict quality control processes

We establish a strict quality control process, including incoming inspection, process control, and final inspection. We use appropriate testing equipment and methods for dimensional measurement, geometric measurement, surface quality inspection, etc.

Train and enhance employee skills

We provide necessary training and skill enhancement opportunities for parts processing personnel to equip them with the correct machining knowledge and skills. Cultivate employees' quality awareness and enhance their ability to control quality and solve problems.

.jpg)

Introducing Statistical Process Control (SPC)

We use statistical tools and methods for process control, monitoring, and analyzing data during processing. We use real-time data analysis to promptly identify process variations and anomalies, take corrective measures, and ensure the stability of processing quality.

Continuous improvement and feedback mechanism

We establish a continuous improvement and feedback mechanism to collect feedback and data from both internal and external sources in order to identify and correct potential quality issues. We continuously improve the quality and efficiency of part processing by analyzing data and taking appropriate corrective measures.

Part Quality Report

Dimensional measurement

We use measuring tools such as calipers, micrometers, vernier calipers, microscopes, etc. to measure various dimensions of the parts. Direct measurement method, comparative measurement method, or optical measurement method can be used.

Geometric measurement

For parts that need to meet specific geometric requirements, such as flatness, roundness, coaxiality, verticality, etc., we can use equipment such as projectors, coordinate measuring machines, and altimeters for measurement.

Surface quality inspection

We inspect the surface of parts for defects such as flatness, smoothness, scratches, oxidation, etc. through visual inspection, touch inspection, magnifying glass inspection, or image inspection.

Functional testing

For certain special purpose parts, we can conduct functional tests to verify their performance and reliability in practical use.

Material inspection

For parts that require specific materials or material performance requirements, we conduct material composition analysis, hardness testing, tensile testing, etc. to ensure that the materials meet the requirements.

Sound and vibration detection

We use equipment such as sound analyzers and vibration measuring instruments to detect parts and assemblies with noise and vibration, in order to evaluate their noise and vibration levels.

How to Work With Us

24/7 Support, Sigma provides the most effective solutions for low volume production and rapid prototyping, just a few steps to experience our excellent customer services.

Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota