Medical Device Industry

If you are looking for a highly skilled manufacturing company with plenty of relevant experience in the medical device industry, Sigma Technik is here to help. We are an experienced company that has the advanced equipment and skilled workforce needed to accurately create complex components from a wide range of materials, which can be customized according to the specific needs and application scenarios of the medical device industry to meet market demand and improve competitiveness.

Manufacturing Solutions for the Medical Device Industry

Medical device manufacturing industry solutions can help enterprises solve the problems and challenges encountered in product design, development, manufacturing, and sales processes, improve product quality and performance, reduce production costs, and improve customer satisfaction and market competitiveness.

Prototyping

Medical device manufacturing enterprises can use rapid prototyping technology to quickly produce prototypes of medical devices, conduct testing and verification, avoid problems in the production process, and improve product quality and performance.

On-demand Production

Medical Device doesn’t require only CNC machining process, which also need a selection of other processes, such as sheet metal fabrication, rapid injection molding, assembly to complete the whole equipment. Sigma offers full turn-key services to solve all your issues at one stop.

Personalized customization

Medical device manufacturing enterprises can customize according to the specific needs and requirements of customers, provide medical device products and services that meet their needs, and improve customer satisfaction and market competitiveness.

quality management system

Medical device manufacturing enterprises can establish a comprehensive quality management system, from raw material procurement to product delivery, strict quality control and testing are carried out at every stage to ensure that the quality and performance of products meet the requirements.

Partner Strategy

Medical device manufacturing enterprises can establish strategic partnerships with relevant partners to jointly develop new products, expand markets, improve service levels and brand image, and achieve mutual benefit and win-win results.

Medical device manufacturing materials

The manufacturing materials of medical devices usually need to have characteristics such as high temperature resistance, corrosion resistance, and biocompatibility.

stainless steel

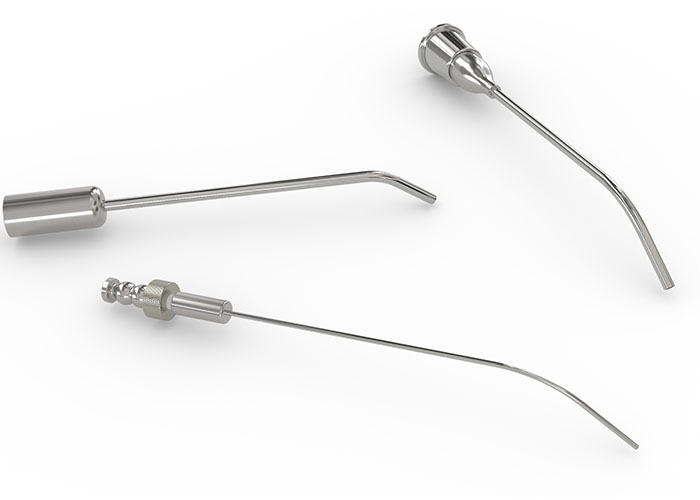

Stainless steel is a commonly used material for making medical devices, which has good corrosion resistance, high-temperature strength, and biocompatibility. It is suitable for making surgical instruments, implants, etc.

Titanium

Titanium alloy is a high-strength, lightweight, and biocompatible medical device manufacturing material, suitable for making artificial joints, implants, dental implants, and so on.

Polymer

Polymer is a lightweight, flexible, and biocompatible medical device manufacturing material suitable for making medical dressings, blood bags, infusion tubes, etc.

Glass

Glass is a non-toxic, odorless, odorless, sterile, and biocompatible medical device manufacturing material, suitable for making syringes, test tubes, etc.

Ceramic

Ceramic is a medical device manufacturing material with high hardness, good biocompatibility, and good corrosion resistance, suitable for making artificial joints, implants, etc.

Medical Device Application

The application range of medical devices is very wide, involving various aspects of healthcare. The application of different types of medical devices in different medical scenarios plays an important role and significance.

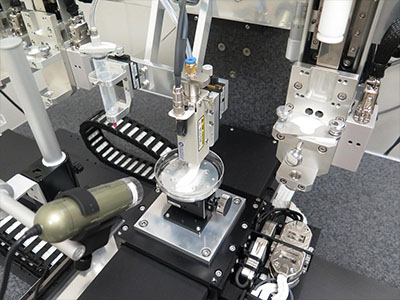

Customized parts for the Medical Device industry

Customized parts need to be designed and manufactured according to the specific usage needs and performance requirements of the device. Usually, manufacturing processes such as 3D modeling, CAD design, CNC machining, etc., require professional technology and experience.

Why Choose Us for Medical Device Manufacturing?

Sigma Technik Limited provides reliable medical device prototype design and production services that can be customized according to customers' specific needs and requirements, including rapid prototyping, bridging tools, and small batch production services, ensuring that customers' needs are met to the maximum extent possible.

Professional medical device design team

We have a professional medical device design team with rich experience in medical device design and development, capable of providing customers with high-quality medical device prototype design and production services.

Advanced technology and manufacturing equipment

We adopt advanced technology and manufacturing equipment to manufacture high-quality and high-performance medical device prototypes, ensuring that the quality and performance of our products meet the standards and requirements of the medical industry.

Strict Quality Control

We adopt a strict quality control system, from raw material procurement to product delivery, every step undergoes strict inspection and testing to ensure stable product quality and performance.

Customized services

We can provide personalized customization services based on customers' specific needs and requirements, including rapid prototyping, bridging tools, and small batch production services, to ensure that customers' needs are met to the maximum extent possible.

Let’s start a great partnership journey!

Frequently Asked Question

Medical devices need to use materials that meet specific usage environments and performance requirements, such as biocompatibility, high-temperature strength, corrosion resistance, and other characteristics. If the material selection is not appropriate, it may lead to unstable and easily damaged use of the device.

The manufacturing process of medical devices requires strict adherence to standardized technological processes, such as 3D modeling, CAD design, CNC machining, etc. If the process is not standardized or the technology is not up to standard, it may lead to issues such as low precision and short service life of the instrument.

Strict quality control is required in the production of medical devices, including raw material inspection, processing inspection, finished product inspection, etc. If quality control is not in place, it may lead to issues such as substandard device quality and compromised safety.

Medical device manufacturing requires continuous research and development innovation to adapt to market demand and technological development. If there is a lack of innovation awareness, it may lead to problems such as outdated products and declining market competitiveness.

How to Work With Us

24/7 Support, Sigma provides the most effective solutions for low volume production and rapid prototyping, just a few steps to experience our excellent customer services.

Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota