Sheet Metal Services

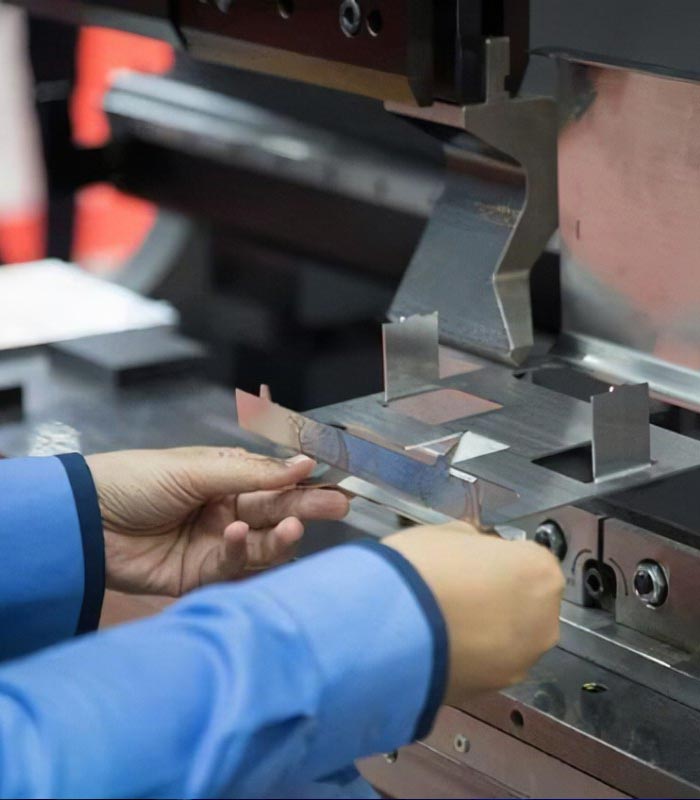

Our facility is designed to support rapid prototyping and low-volume production with a wide range of high-precision tooling and equipment to meet any task.

On-demand Sheet Metal Fabrication

Our high-quality metal fabrication & engineering services help you to Accelerate your product development.

- Quota in couple of hours

- Factory based online manufacturing

- Transparent project management

- Easy communication in various ways

- Lead time as fast as 3 days

Customization of sheet metal processing services

We provide metal cutting and bending services to assist customers in sheet metal component processing. Automated cutting processes can ensure high precision and quality of finished components.

laser cutting

A cutting process that can be used to cut metal and non-metallic materials of different material thicknesses. The laser beam that has been guided, shaped, and assembled lays the foundation for this.

Metal punching

A common manufacturing process used to produce large quantities of metal components. It utilizes mechanical operations to shape metal sheets at high speeds through a stamping machine according to mold design trends, in order to achieve the desired shape and size.

Bending

It involves applying force to sheet metal parts to change their geometric shape. This force will generate stress on the metal plate that exceeds its yield strength, causing physical deformation of the material without rupture or failure.

Material Selection for Sheet Metal Fabrication

Aluminum

SPCC Steel (non-treated)

SGCC Steel (Galvanized steel)

Stainless Steel

Brass

Copper

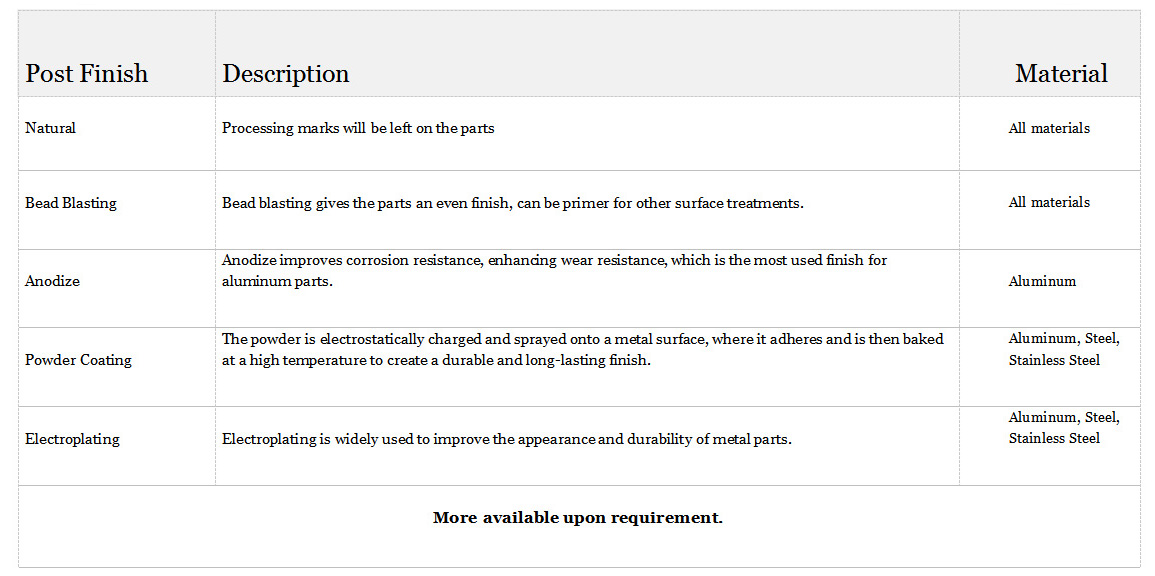

Surface Finishes for Sheet Metal Parts

Surface finishes of metal plate parts refers to the processing and treatment of the surface of metal plate parts to improve their surface quality and performance, increase their corrosion resistance, hardness, wear resistance, and other characteristics, and also improve their aesthetics.

Sheet Metal Fabrication - from rapid prototyping

to large scale mass production

Sheet metal is a cost effective and efficient process, that supports high-volume commodity products and low-volume, even one-of-a-kind application.

Rapid Prototyping

When it comes to rapid prototyping, every day counts. Try our rapid prototyping services, get the parts as fast as 1 day.

Low Volume Production

Sigma offers smart solution to produce the low volume production in a cost-efficient way.

Why choose our customized sheet metal manufacturing service?

We provide high-quality and high-precision sheet metal manufacturing services, and support on-demand customization.

Team

We have a professional sheet metal processing team with years of experience and rich technical knowledge, which can provide customers with high-quality sheet metal processing services.

Advanced equipment

We have advanced CNC sheet metal processing equipment, including laser cutting machines, CNC punching machines, CNC bending machines, etc., which can ensure the accuracy and quality of sheet metal processing.

high quality materials

We use high-quality sheet metal materials, including stainless steel, aluminum alloy, etc., which can meet the different needs and requirements of customers.

On demand customization

We provide customized sheet metal processing services that can be customized according to customers' needs and requirements to meet their different needs.

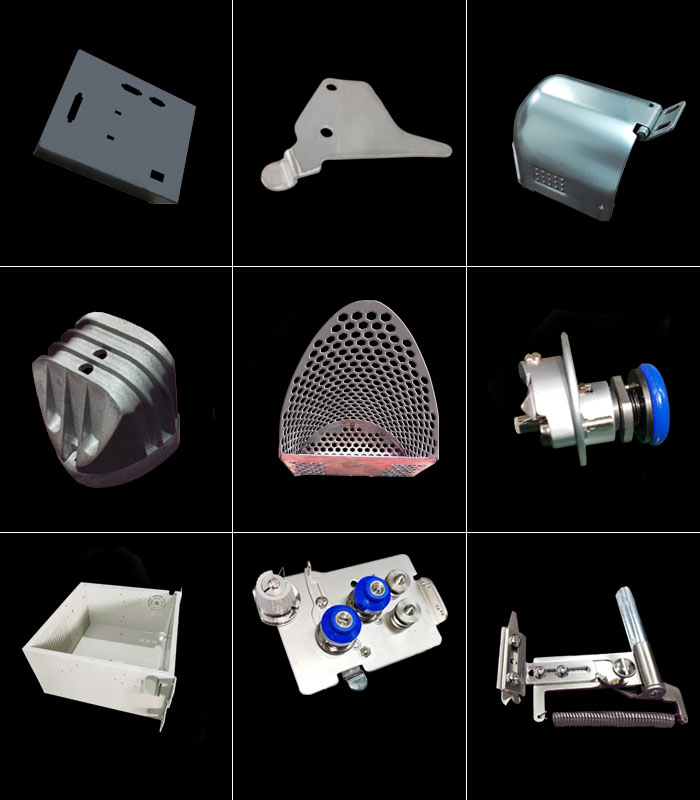

Sheet metal manufacturing applications

Sheet metal processing can meet the production needs of various shapes and sizes of components, and can meet the needs of small batch, multi variety, and rapid production, with relatively low manufacturing costs.

Let’s start a great partnership journey!

Sheet Metal FAQs

During sheet metal processing, due to the characteristics of materials and processing methods, parts can deform. The solution is to adjust the processing technology and methods, strengthen the support and fixation of materials, and use automated processing equipment to solve the problem.

Welding quality issues in sheet metal processing may lead to issues such as insufficient component strength, porosity, and cracks. The solution is to use high-quality welding materials and equipment, strengthen monitoring and control of the welding process, and ensure that the welding quality meets the requirements.

After the sheet metal processing is completed, surface treatment is required, such as spraying, electroplating, etc. Poor surface treatment may lead to corrosion, oxidation, and other issues. The solution is to use appropriate surface treatment methods and equipment, strictly control the quality of the surface treatment process, and ensure that the surface treatment effect meets the requirements.

During sheet metal processing, dimensional deviations may result in parts being unable to be assembled or poorly assembled. The solution is to strengthen dimensional control and monitoring during the machining process, use high-precision equipment for machining, and compensate for dimensional errors during the machining process.

Quality issues may occur during sheet metal processing, such as surface burrs, cracks, pores, etc. The solution is to strengthen quality control and inspection, use advanced testing equipment and methods, and ensure that the quality of each product meets the requirements.

How to Work With Us

24/7 Support, Sigma provides the most effective solutions for low volume production and rapid prototyping, just a few steps to experience our excellent customer services.

Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota