What is an SLA? SLA deep analysis

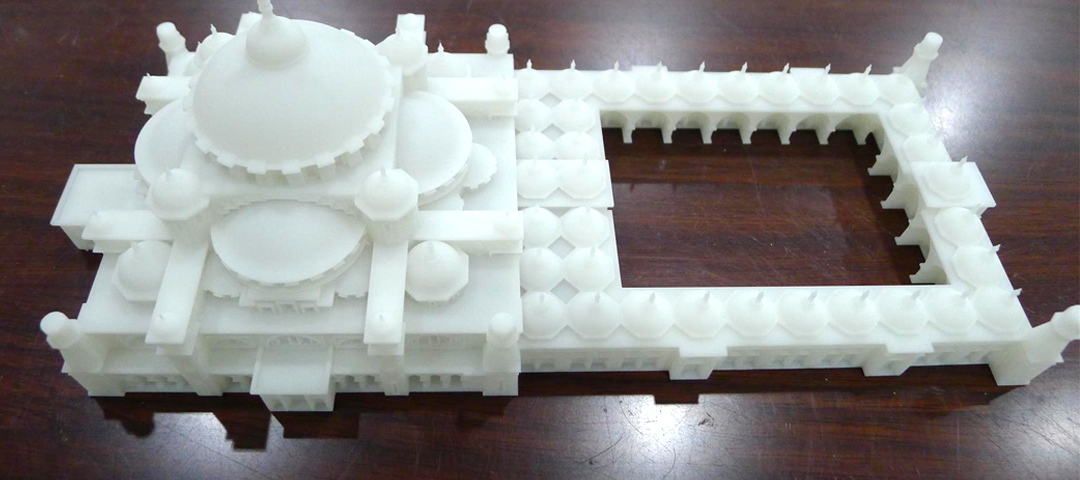

SLA is a commonly used method for rapid prototyping and 3D printing technology. SLA is a process of creating a solid model by using photosensitive resin for layer by layer curing.

During the SLA process, it is necessary to first use computer-aided design (CAD) software to create a three-dimensional digital design of the model. Then, input the design file into the SLA machine. The SLA machine includes a laser beam and a slot filled with photosensitive resin.

During the printing process, the laser beam irradiates the photosensitive resin layer by layer, causing it to solidify or aggregate. The irradiation path of the beam is controlled by a computer, gradually solidifying the resin into the desired shape based on the design contour of each level. Once one layer is cured, the printing platform will sink a certain distance, so that the resin level of the next layer is above the new printing layer, and then repeat the curing process until the entire model is printed.

After printing is completed, the solidified model will be removed and subjected to subsequent processing, such as cleaning, removing support structures, surface treatment, etc. Ultimately, models printed through SLA can be used in fields such as prototype production, mold manufacturing, medical devices, and art.

The main advantages and disadvantages of SLA

Advantages

SLA printers can achieve very high printing accuracy, typically in the range of tens of micrometers. Suitable for applications that require high precision and detail, such as prototyping, medical devices, etc.Due to the photosensitive resin used in SLA printing process, it can form a smooth surface after photocuring, with good surface quality and detailed performance.

SLA printers can print models with complex structures and geometric shapes, including voids and internal details. Usually applied in the fields of design engineering and art.

Compared to other 3D printing technologies, SLA printers typically have faster printing speeds. It is very useful in scenarios that require rapid prototyping and production.

Disadvantages

Compared to other 3D printing technologies, the material selection for SLA printers is relatively limited. There are relatively few types and colors of photosensitive resins, which may not meet certain specific needs.SLA printed models typically require post-processing, including cleaning off uncured resin, removing support structures, and performing surface treatment. These additional steps may increase printing time and labor costs.

The cost of SLA printers and photosensitive resins is usually high, which makes SLA printing relatively expensive. For projects with large-scale production or limited budgets, cost may be a factor to consider.

Some photosensitive resins may contain chemicals and may pose certain health risks. Therefore, it is necessary to pay attention to safety measures and appropriate ventilation when using SLA printers.

Post processing of SLA and how to remove supporting materials

Post processing steps

Remove the printed model from the printing platform. Then, place the model in a container filled with a special cleaning solution, such as isopropanol (IPA). Gently stir or ultrasonic clean in the cleaning solution for a period of time to remove the uncured resin on the surface of the model.After cleaning, rinse the model with clean water or another cleaning solution to remove residual cleaning agent.

Place the model in a well ventilated area and let it dry naturally or use a hair dryer or oven to accelerate drying.

As needed, surface treatments such as polishing, spraying, polishing, etc. can be applied to the model to further improve its appearance and texture.

Remove support material

In the SLA printing process, support structures are usually added to support the suspended part of the model and avoid deformation. The method of removing supporting materials depends on the materials used and the shape of the supporting structure.

Manual removal

Carefully remove the support material manually using tools such as scissors, tweezers, and scrapers. This method is suitable for small or simple support structures.cutting

Use cutting tools such as wire cutters, saws, etc. to cut along the contact surface between the support structure and the model. Then, remove each part of the support structure one by one.dissolution

Some supporting materials can dissolve in specific solvents. If the support material you are using can be dissolved, you can place the model in an appropriate solvent to dissolve the support material.heat treatment

For certain supporting materials, heat treatment methods can be used. For example, use a hot air gun or flame to gently heat the support structure to make it soft and easy to remove.

Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota